About Us

BLACKRIVER Stainless Tube Inc.

Can't seem to find what you are looking for? We specialize in supplying Exotic and uncommon sizes (metric and inches) in the metal industry. With over 30 years in the business, our experience and expertise will help you solve your most challenging pipping steel tube needs.

Stainless Steel Pipe

Approved/Non approved mill

Pressure fittings and flanges

Now in stock 316H Plate in the USA

Pressure fittings and flanges

Now in stock 316H Plate in the USA

Exotic Tubing and Fittings

Welded and Seamless

Sheet/Plate

Nickel Alloys

Cobalt Alloys

Sheet/Plate

Nickel Alloys

Cobalt Alloys

Strength & Quality According to Standard

The following formulas are used to determine quality and strength

Barlow's Formula is Used to Determine

- Internal Pressure at Minimum Yield

- Ultimate Bursting Pressure

- Maximum Allowable Operating Pressure

- Mill Hydrostatic Test Pressure

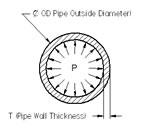

The Formula is Expressed as P=2St/D

- P = pressure, psig

- t = nominal wall thickness, in inches (i.e. .375)

- D = outside Diameter in inches

- S = allowable stress in psi, which depends on the pressure being determined utilizing Yield or Tensile depending on what is trying to be determined

For Example

Internal Pressure at Minimum Yield:

S = SMYS - minimum yield for grade of pipe

Ultimate Bursting Pressure

S = SMTS - minimum tensile strength for grade of pipe

Maximum Allowable Operating Pressure

S = SMYS - reduced by a design factor

Mill Hydrostatic Test Pressure

S = SMYS - reduced by a design factor depending on OD and grade

S = SMYS - minimum yield for grade of pipe

Ultimate Bursting Pressure

S = SMTS - minimum tensile strength for grade of pipe

Maximum Allowable Operating Pressure

S = SMYS - reduced by a design factor

Mill Hydrostatic Test Pressure

S = SMYS - reduced by a design factor depending on OD and grade